Lantek, a global benchmark in sheet metal software solutions, and TCI Cutting, a specialist in high-autonomy industrial cutting systems and intelligent automation through its MAS Concept® model (Machinery, Automation, and Software), have jointly developed an innovative automated sheet unloading system. Successfully implemented at several strategic customer sites, this solution optimizes post-cutting material handling by eliminating manual intervention and significantly reducing downtime in the production cycle.

Efficient Automation in Sheet Unloading

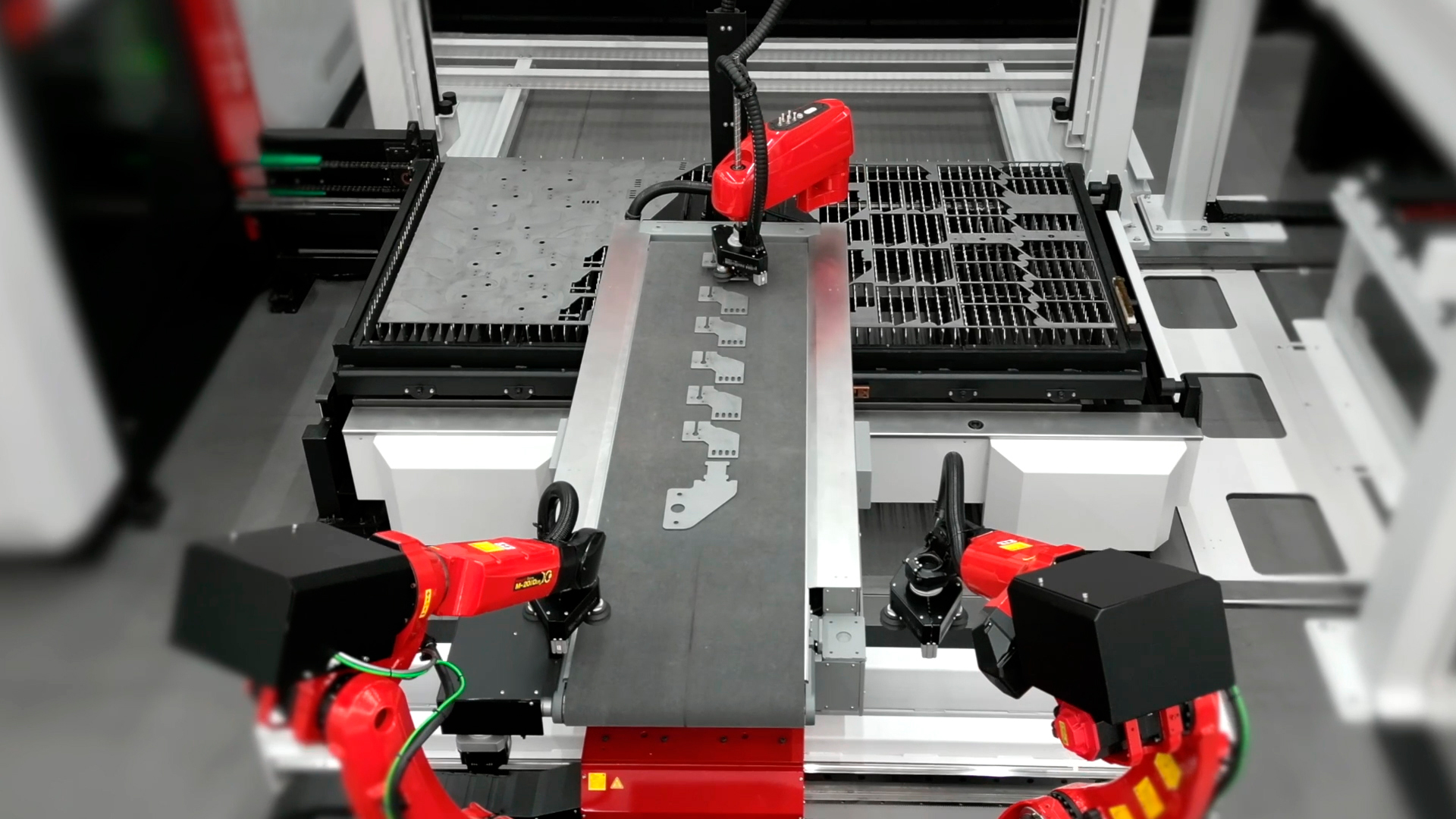

Integrated with Lantek Expert software, the system leverages technology developed by TCI Cutting, combining an intelligent suction cup grid with its Automation Systems Load & Unload® platform for laser cutting machines. This integration enables fully automated and highly precise removal of parts directly from the cutting table.

The system detects the exact position of each part, activates only the required suction cups, and ensures precise handling based on the geometry and center of gravity of each piece. As a result, parts are unloaded without error, avoiding the suction of skeleton material or unwanted components and ensuring that each part is safely and accurately handled.

Machines equipped with TCI Cutting’s Automation Systems Load & Unload® manage material loading and unloading autonomously and can be connected to intelligent storage systems. Once the cutting process is complete, the processed table exits the working area, and the suction system automatically removes the finished parts—without any operator intervention—streamlining the production flow while improving both safety and ergonomics.

"Automating the unloading process without interrupting the cutting cycle is essential to improving efficiency in sheet metal workshops. This solution delivers precision, flexibility, and better machine utilization, reducing operator workload and optimizing the entire production process," explains Francisco Pérez, OEM Channel Director at Lantek.

A Flexible and Automated Solution to Optimize Production

“This system not only prevents unloading errors but also provides a flexible, modular, and fully customer-adaptable solution,” TCI Cutting states. Unlike traditional systems that only allow stacking of identical parts, this solution deposits all cut parts at a single point, giving the operator freedom to organize them according to production needs.

Suction cup activation can also be manually configured, giving users full flexibility to manage parts with micro-joints or complex geometries. Integration with Lantek Expert ensures advanced process control, allowing operators to fine-tune settings based on production requirements and maximize operational efficiency in every cycle.

Scalable, Modular, and Customizable Automation for the Sheet Metal Industry

Initially developed as a tailor-made project, this technology is now available for broader implementation. It stands as an adaptable and scalable automation solution for the sheet metal industry. With this innovation, Lantek and TCI Cutting strengthen their commitment to industrial digitalization and production process improvement—offering sheet metal manufacturers a powerful tool to boost productivity, streamline workflows, and enhance competitiveness.