Lantek Expert Punch

Lantek Expert Punch is a specially designed CAD/CAM nesting software designed for automating the programming of CNC punching machines. It is the result of over 30 years of Lantek experience in close collaboration with machine tool manufacturers and users.

Lantek Expert Punch offers an advanced, intuitive, and friendly interface that improves programming efficiency.

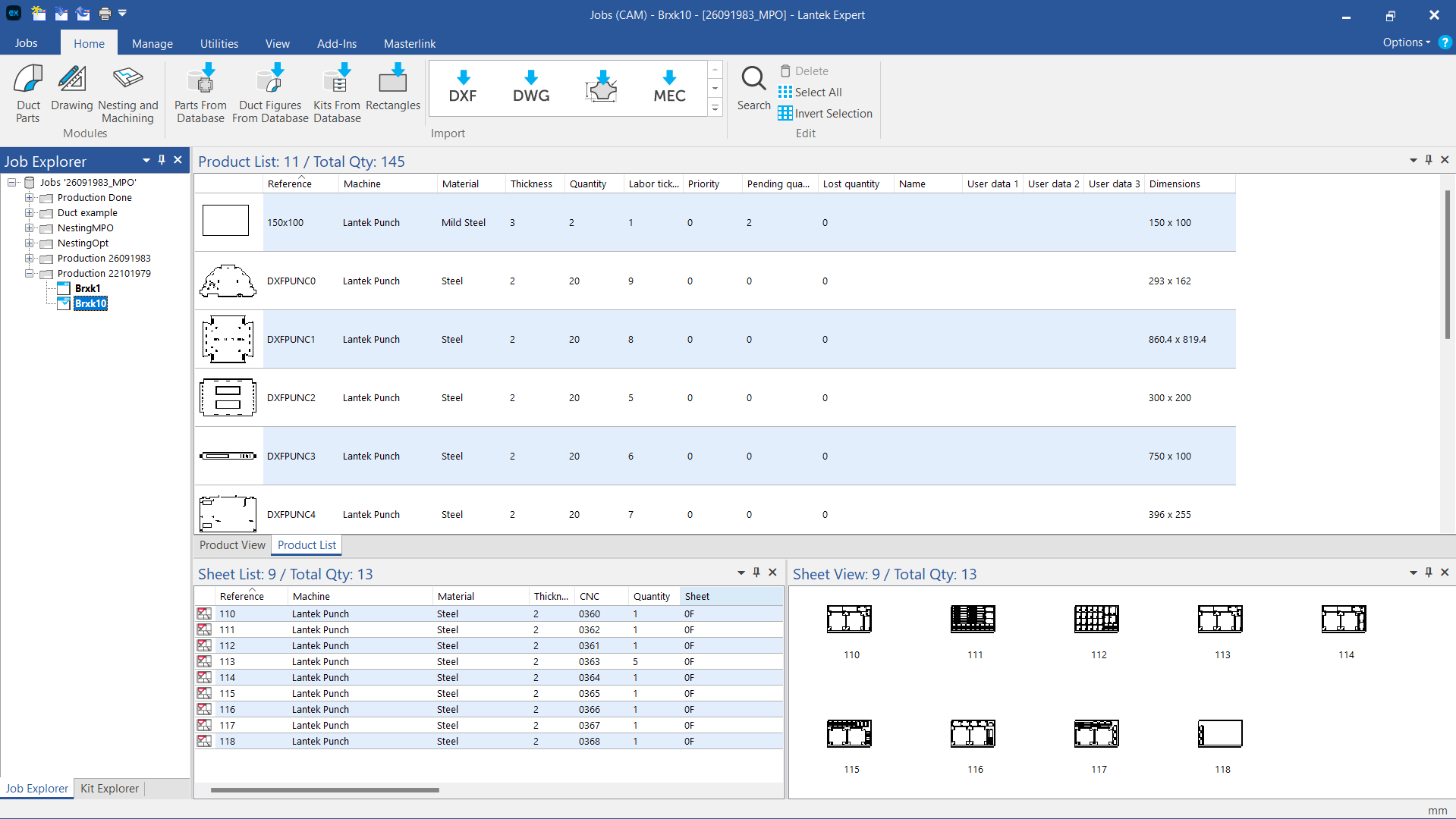

1.jpg)