Contributed by Mario Rodríguez, Product Manager of Lantek

Each of these programs has its own characteristics, functionalities, and especially, its own format for storing parts/assemblies in files.

In the metal production market, it’s common for many companies (our clients) to only use one of these 3D CAD programs both when designing their own products and exchanging designs with their collaborating companies. This limits their interoperability in the market as they frequently have to use non-proprietary intermediate formats (such as STEP, IGES, SAT), which is ultimately inefficient and not always possible.

The number of 3D design platforms and programs has increased in recent years, with the emergence of new (and smaller) competitors in the 3D CAD market, making the range of programs used by our clients to make their designs increasingly heterogeneous.

When one of our clients receives a 3D design, the different tasks to be carried out, with the help of 3D CAD software, are:

1) an exploded view of all design components

2) the unfolding of the pieces of sheet metal and conversion into 2D format

3) identification of the other elements (tubes, profiles and other components)

If they don’t have a 3D CAD tool compatible with the 3D design format, the user has to convert it into a format compatible with their 3D CAD software, which is not always possible.

In addition to this, one key element in the production of folded pieces is taking into account which tools are going to be used to fold the piece once it is cut, given that this has an influence on the size of the piece to be cut. In other words, when unfolding a 3D piece to 2D, the tool that will be used in its folding production process has to be considered.

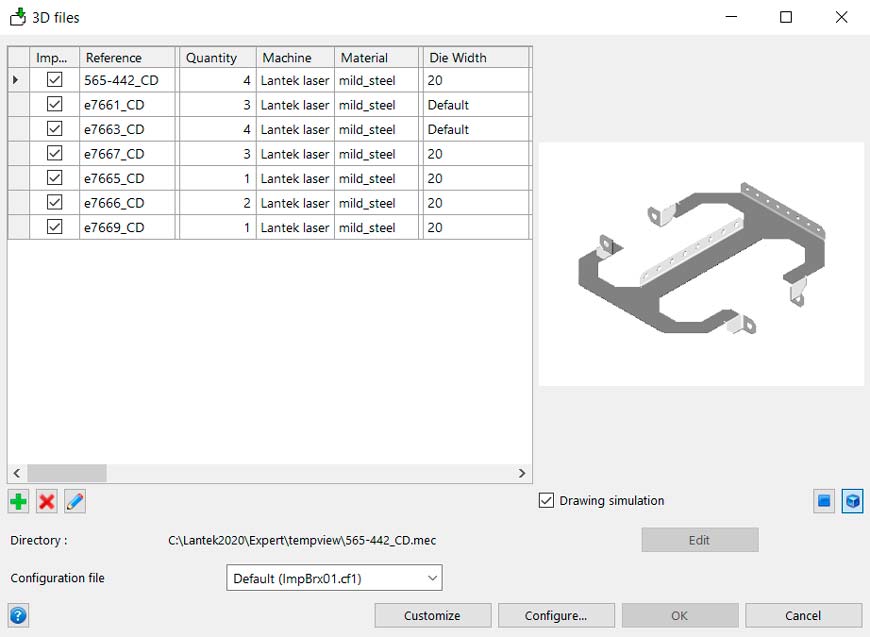

A2N (Assembly To Nesting) is the 3D geometry importer (assemblies and single pieces) that Lantek provides for its users, allowing all the steps explained above to be carried out automatically, without manually needing to resort to external tools.

A2N is compatible with the vast majority of 3D formats on the market and allows the user to preview the parts to be unfolded and to choose the folding tool for the pieces of sheet metal, so that the geometry to be cut in Lantek Expert is exactly what is required in order to proceed with the folding process, resulting in a part that matches the one designed in 3D.