CEO Tobias Grimmig calls digitalization the company’s “safeguard for the future.” Guiding him along this path: Jens Schamberger of Lantek, whom he considers the crucial link between operations and IT.

High-Volume Sheet Metal Fabrication with Rapid Turnaround

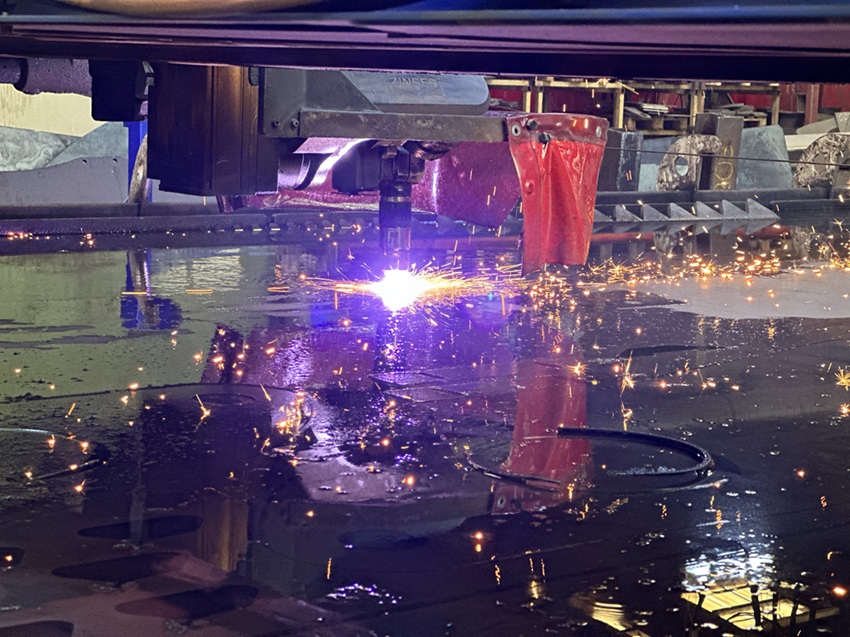

Arpogaus builds welded structures weighing up to 20 tons and measuring up to 20 meters long for the construction equipment and large-scale special machinery sectors. The 70-person team in Wiggensbach, Bavaria, produces around 4,000 prototypes and small-series components per year across a 7,000-square-meter shop floor. The full workflow—cutting (often with complex bevels for weld prep), welding, milling, drilling, final assembly, and painting—takes just five weeks from order to shipment.

Arpogaus was founded in 1959 by Rudolf Arpogaus, who also kicked off what remains a longstanding partnership with construction machinery giant Liebherr—still one of Arpogaus’ biggest clients today.

Zero Scrap Policy: How Arpogaus Maximizes Sheet Metal Efficiency

The cutting department at Arpogaus operates with almost surgical precision. “We don’t have any sheet metal waste,” says Grimmig. “We always cut full sheets. Anything less and we wouldn’t be efficient.” This requires a job-spanning strategy, where one sheet may yield parts for as many as 60 different orders. On top of that, a single order might require 30 different sheets with varying thicknesses and grades.

Managing this complexity fell to Elke Gast and her colleague Peter Gast, head of planning and production. For years, they kept everything under control using a highly structured system supported by massive Excel spreadsheets that sprawled across a dedicated planning table.

“Elke Gast is reliable, meticulous, and precise. Despite all her notes and lists, nothing ever went wrong,” Grimmig says with respect. But he also had to plan for the future: “When these experienced people retire, we lose a wealth of knowledge that’s hard to replace. And with our growth came a level of complexity that our previous system couldn’t handle anymore. At some point, it became clear—we had to digitize.”

Transitioning from CAD/CAM to MES for Smarter Manufacturing

Arpogaus had already been using Lantek Expert—a CAD/CAM solution—to control their plasma and oxy-fuel cutting machines from ZINSER. Jens Schamberger, now with Lantek, had previously worked at ZINSER and knew the challenges inside and out. Grimmig describes Arpogaus as “power users” of the software and credits Schamberger for connecting operational needs with Lantek’s development team. “We’ve known each other for over ten years. He fights for what we need. Where the software didn’t quite fit, he bridged the gap with his hands-on experience.”

It was Schamberger who recommended Lantek MES Manager to help reduce the workload in production planning and move toward automation. “Before MES, Arpogaus used to register entire orders as assemblies in Lantek Expert—sometimes with up to 6,000 parts. That bogged the system down and made nesting incredibly time-consuming,” Schamberger explains.

Nesting Time Reduced from 20 to 5 Minutes with Lantek MES

“MES makes our planning process much easier,” says Grimmig. Now, orders are entered as assemblies with sub-jobs, and parts are tracked individually through production. “Previously, it took about 20 minutes to create a nesting plan for one sheet, manually pulling parts from various Excel files. Now it takes five minutes—the system automatically pulls relevant parts from all active jobs.”

Using Lantek Manager, production managers can track every part’s status: what’s already cut and processed, and what still needs to be done. They can also prioritize based on delivery deadlines, and the system constantly updates them on which assemblies are complete and which are pending.

Intelligent Nesting and Production Planning with MES

During implementation, Arpogaus and Lantek took a phased approach. A test environment was set up, and Schamberger provided in-house training. “Elke Gast was very involved during the implementation,” recalls Grimmig, though she expressed initial concerns: “If this fails, the whole operation comes to a halt,” she’d warn repeatedly.

But nothing failed—and performance improved. “If there’s space left on a sheet, the Manager shows us which parts from which orders match in grade and thickness,” Grimmig explains. This lets them cut parts well in advance of when they’re actually needed. “It also tells us which sheet needs to be cut next to hit upcoming delivery deadlines. The software brought us tremendous gains in productivity and efficiency.”

Best of all, says Grimmig, he no longer has to rely on a single person’s knowledge: “Before, only Elke could manage this process. Now, anyone can step in—the software handles the sorting and allocation.”

Replacing Excel Spreadsheets with Centralized MES Data

There’s still work ahead. “We have about 1,000 active assemblies spread across 20 to 30 Excel files. They all need to be imported into MES,” says Grimmig. A majority of the data was imported using a macro developed by Lantek’s technical team. The rest—highly customized legacy tables—still have to be entered manually.

How Customer Feedback Drives Lantek MES Development

For Lantek, companies like Arpogaus are key drivers of software evolution. “Requests such as mirrored weld seams for left/right parts or importing 3D bevels were passed on to our developers in Spain and are being included in future updates,” says Schamberger. He’s also forwarded specific requests related to report customization.

What’s next on the digitalization roadmap? Grimmig wants to connect Lantek’s software directly with the company’s ERP system to eliminate manual order entry. “But we’re not rushing it. First, our team needs to get fully comfortable with the current solutions. We want to bring them along in this process—not overwhelm them.”