Nesting optimization is typically focused on maximizing material utilization. But that approach doesn’t always translate into overall efficiency—especially when it creates bottlenecks in downstream processes. Lantek’s latest update introduces a new feature in its software suite: nesting by attribute, allowing manufacturers to set custom priorities for how parts are arranged on sheet metal, based on operational needs. The feature was developed in direct response to customer requests.

“Modern laser cutting machines are so fast that shop floor operators often struggle to keep up when sorting cut parts,” explains Christoph Lenhard, Sales Director at Lantek for Germany, Austria, and Switzerland. “Sometimes, grouping parts from different jobs on a single sheet can make material usage more efficient—but it can also disrupt the production flow if the parts require different post-processing steps. Looking at the full production chain, it’s often more effective to nest parts according to how they’ll be handled next, even if it means sacrificing some material efficiency.”

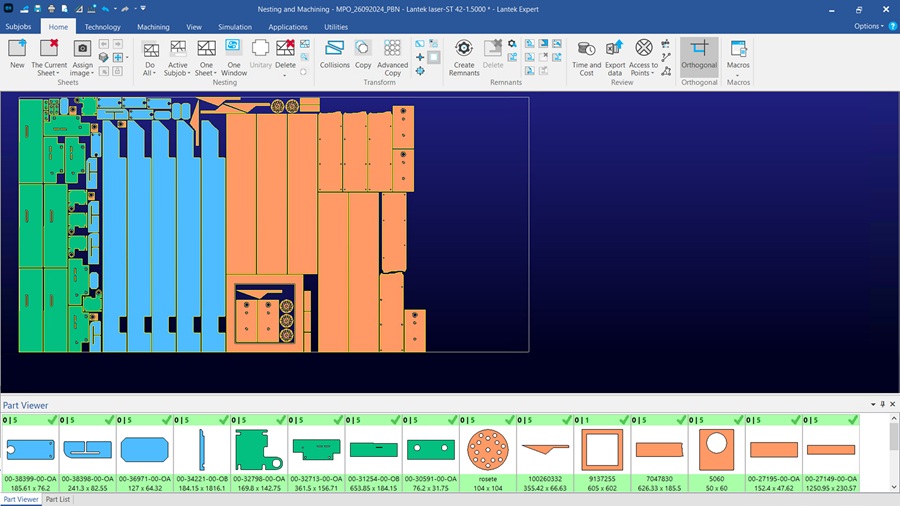

Clearer Layouts, Faster Identification

Available in version V44 of Lantek Expert, the new nesting by attribute tool is designed to simplify part identification and improve operator workflow. “It’s intuitive and easy to use,” says Lenhard. “It helps machine operators instantly see which parts belong to which job, reducing errors and saving time.”

The feature lets users group and organize parts on a sheet—or in specific areas of a sheet—based on selected criteria. Parts from the same job or production stage can be color-coded, separated by offset zones, or divided by visible lines to make them easier to identify and remove. Users can define nesting priorities using any attributes stored in Lantek Expert or Lantek MES, such as delivery deadlines, follow-up processes, container type, associated job orders, or assemblies. During nesting, parts that match the selected properties are prioritized; others are placed in remaining space.

Developed in Response to Customer Feedback

This feature wasn’t developed in isolation—it came directly from industry needs. “At Lantek, we maintain a global database where customer feature requests are collected,” says Lenhard. “When enough users request a specific function, it goes into our development roadmap.” The response to property-based nesting has been overwhelmingly positive. “Customers appreciate the flexibility,” he adds. “In some cases, full material optimization is the right call. But in others, it’s far more practical to nest in a way that supports faster, more efficient part handling on the shop floor.”