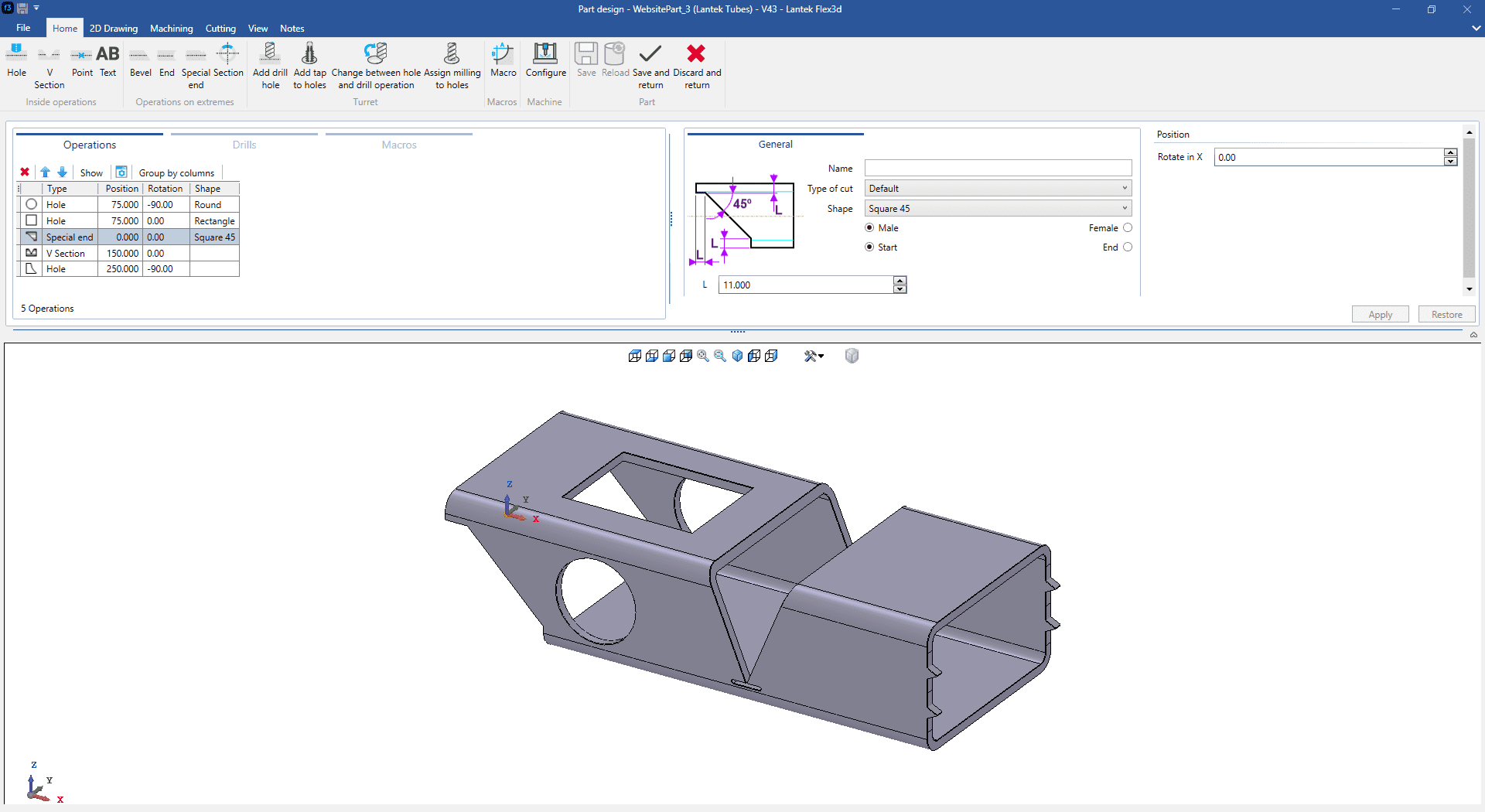

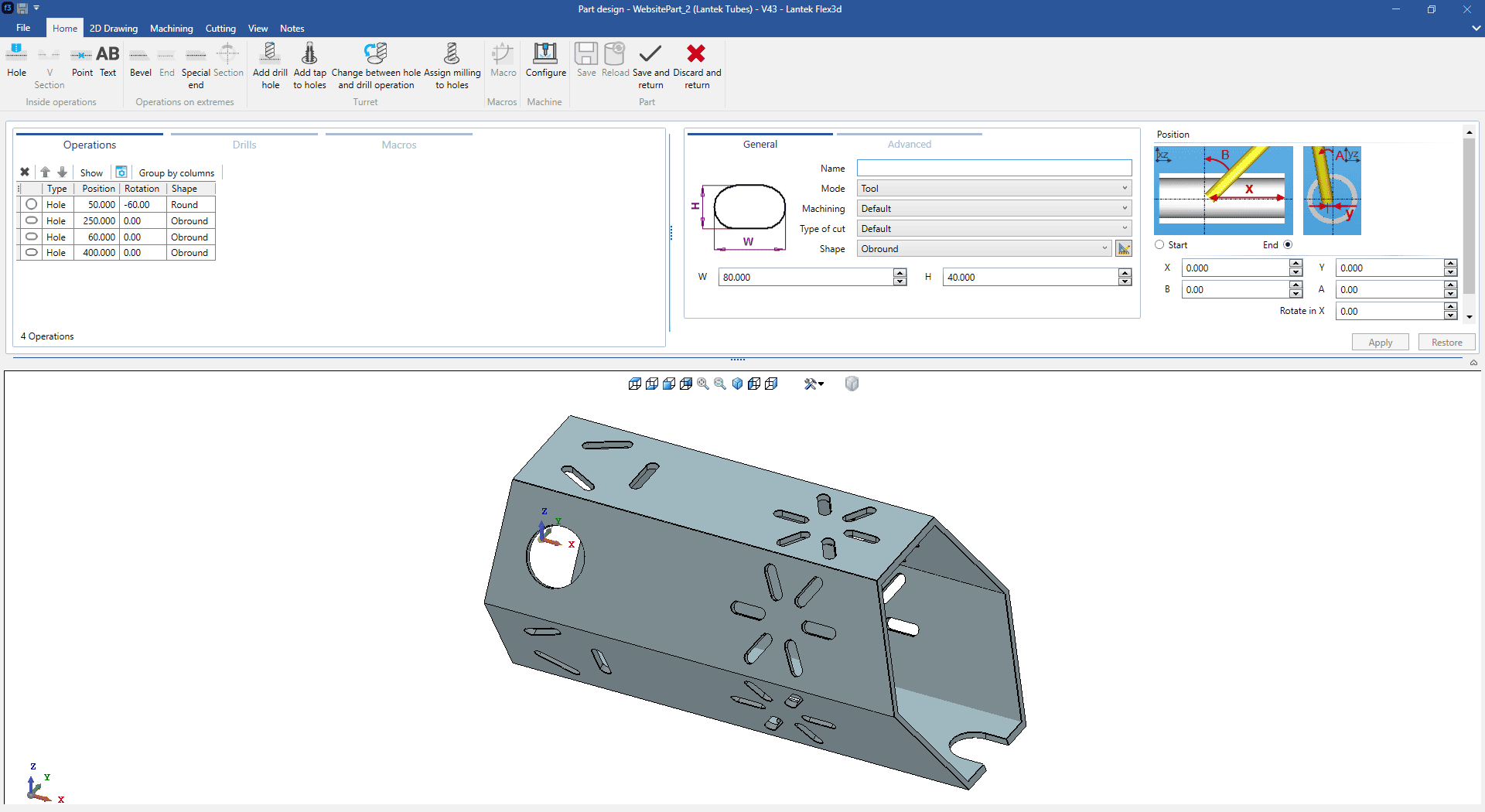

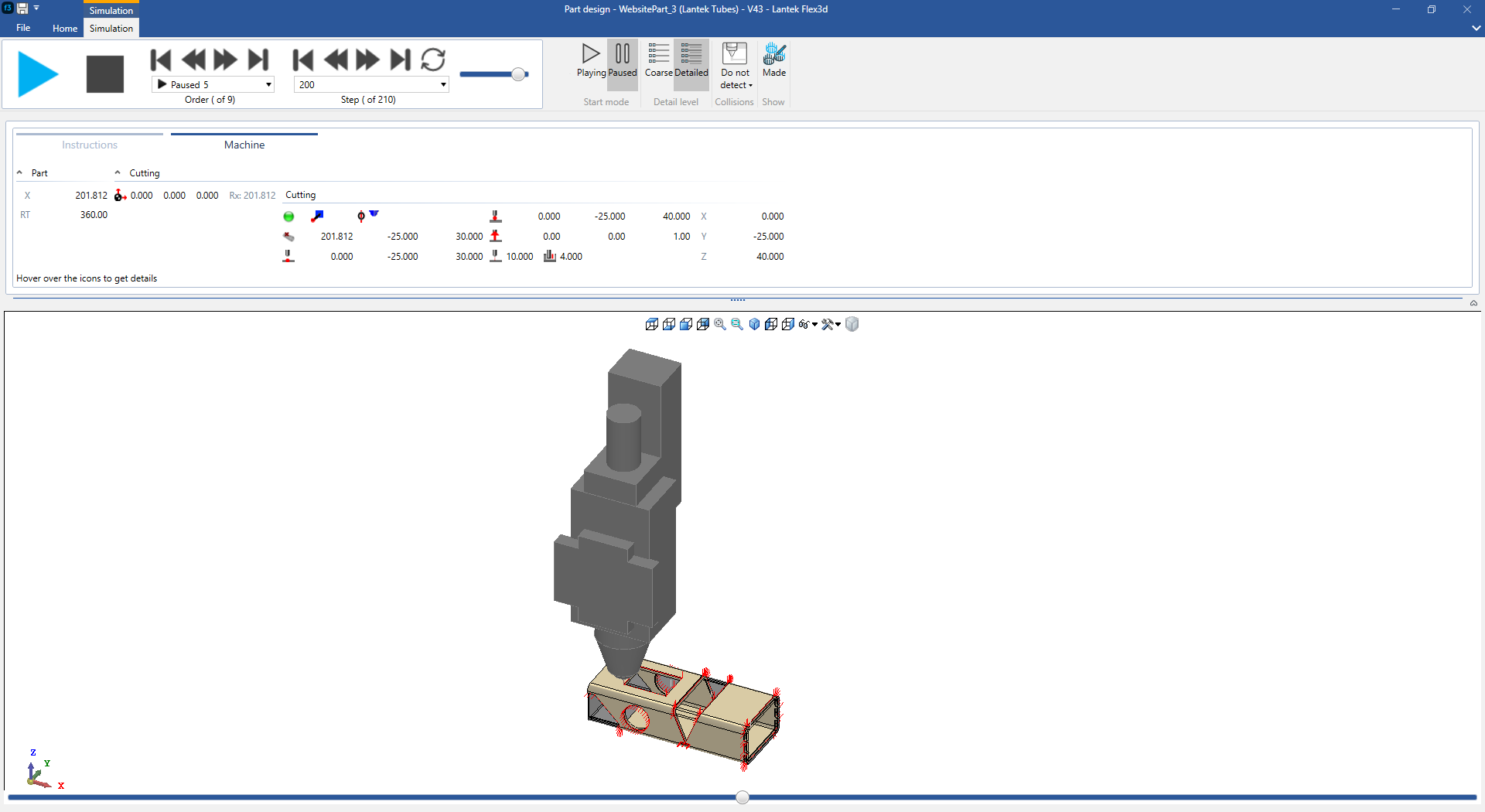

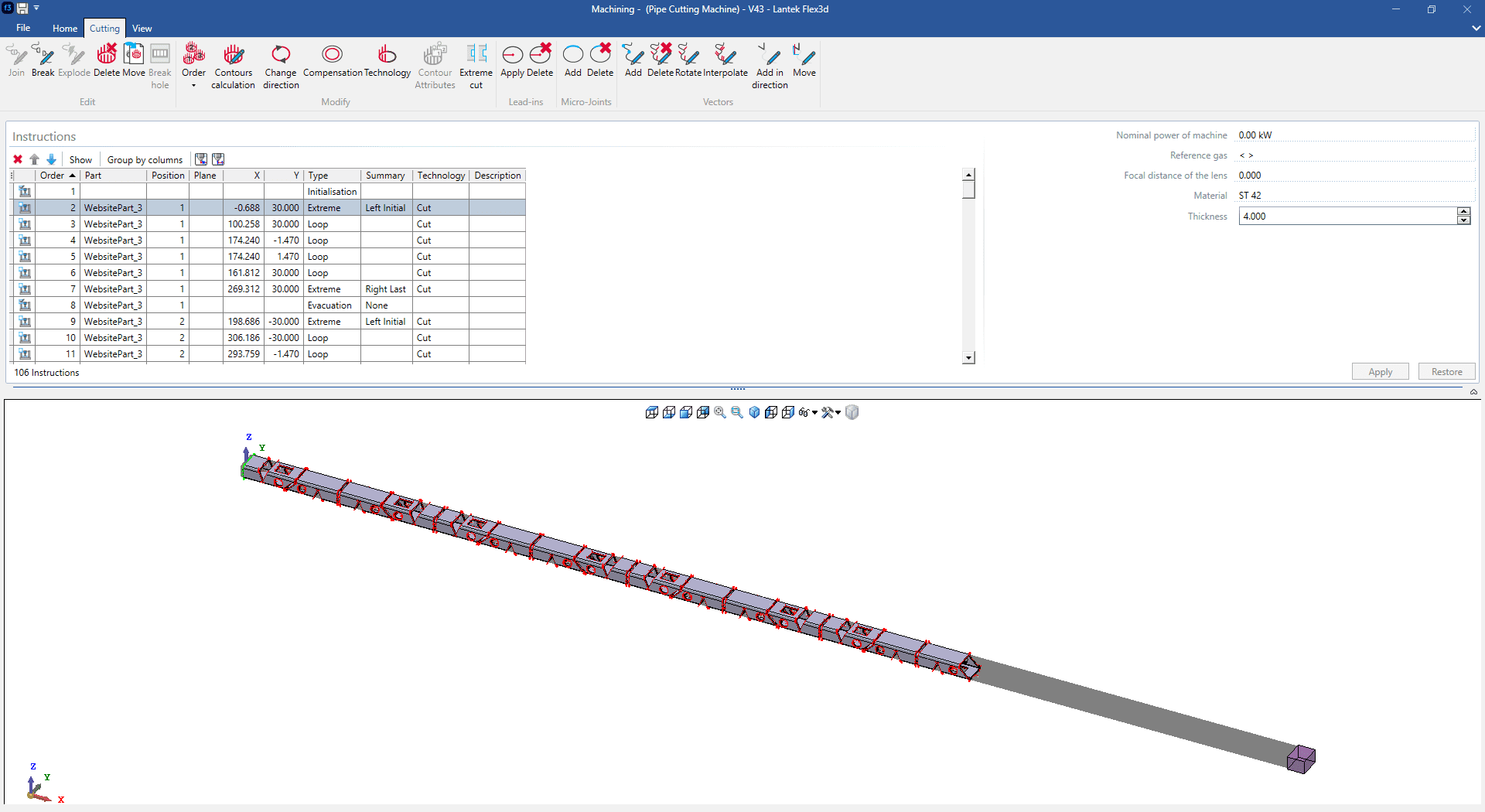

Lantek Flex3D Tubes

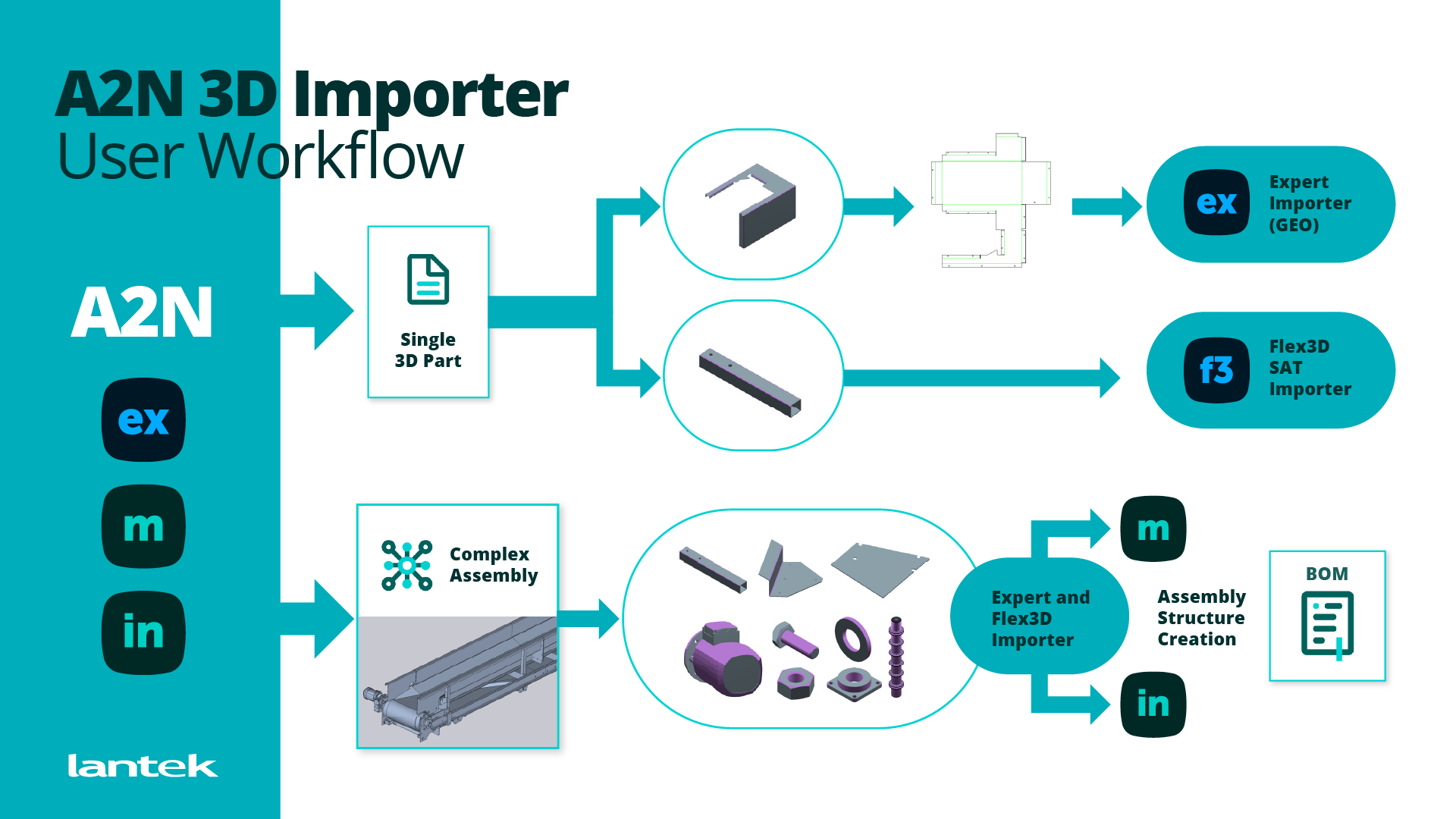

Lantek Flex3D Tubes is a CAD/CAM software system for designing, nesting and cutting parts of tubes and pipes.

Lantek has used all of its experience and proficiency gained in design systems and programming for sheet metal cutting, punching and bending machines and applied it to the tube cutting sector – regardless of the type of machine.