Intelligent Cutting Tools to Prevent Production Interruptions

One standout feature in Lantek Expert is its internal contour fragmentation capability. It allows large, internal sections of leftover material to be cut into smaller, more manageable fragments that can drop through the machine’s slats with ease. This prevents unwanted collisions with the laser head, avoids material build-up on the cutting table, and helps maintain a continuous workflow.

By addressing this challenge at the programming stage, Lantek Expert eliminates the need for manual intervention later in the process—saving both time and labor. Users can select from different strategies to manage internal remnants, depending on their specific application needs.

One method involves assigning micro-joints—small connections that keep internal areas secured to the surrounding material. These help prevent the unwanted movement or tipping of loose material during the cutting cycle. Alternatively, the software allows the operator to choose direct fragmentation of internal leftovers, giving full flexibility based on machine type, part complexity, or cutting method.

Spiral Cutting: A Cleaner, More Efficient Way to Handle Holes

Another key tool within Lantek Expert is the spiral cutting feature for circular holes. This functionality is designed to efficiently eliminate the leftover core material inside holes, letting it fall cleanly into the machine bed. The benefit is twofold: it minimizes the risk of material collisions and supports a smoother, more consistent cutting process.

The spiral technique reduces the number of stop-start motions, eliminates sharp corners, and ensures a cleaner finish. It’s a clear advantage for shops aiming to improve both cutting speed and tool longevity, particularly in high-volume environments.

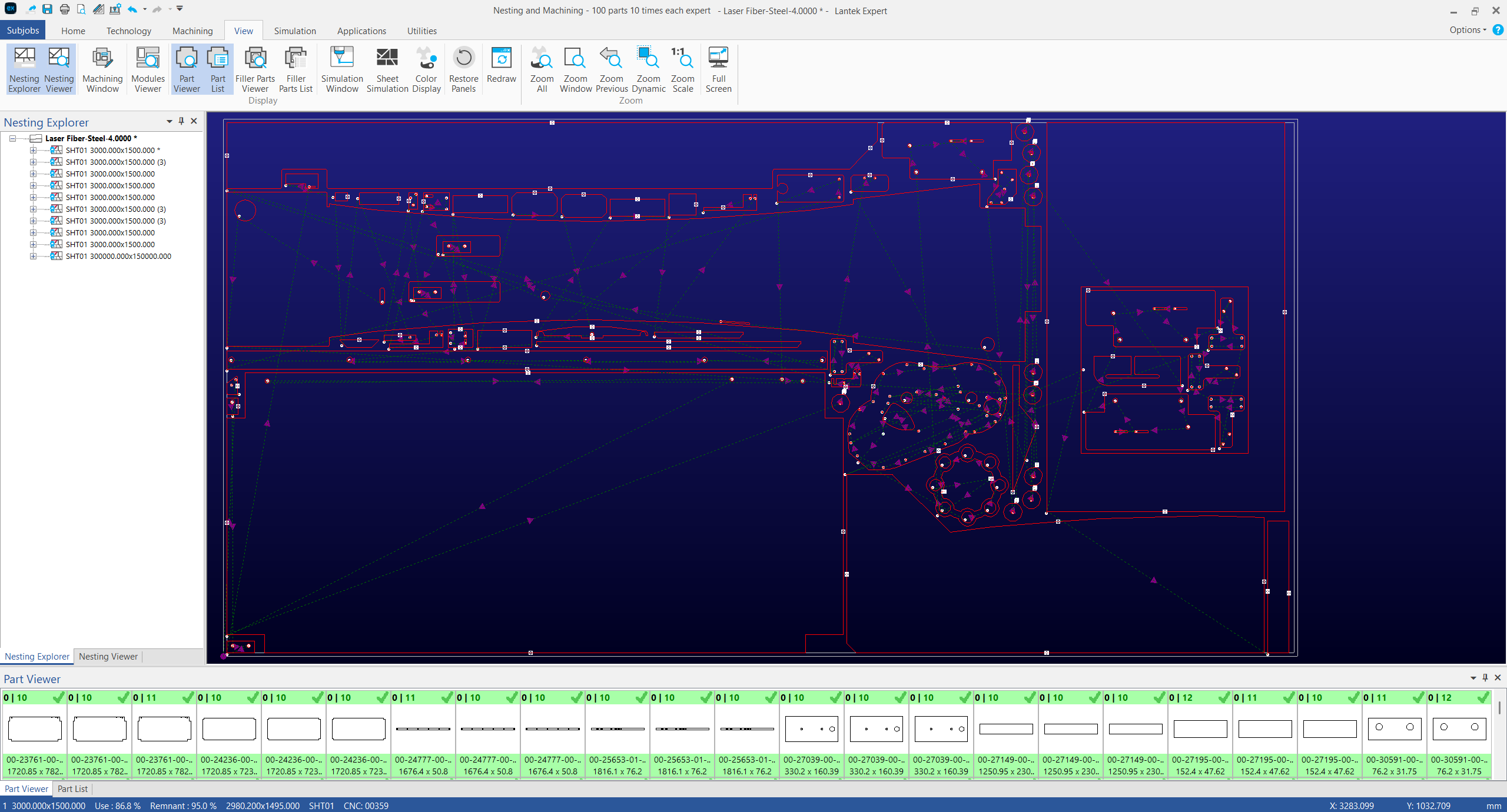

ICA: Predictive Collision Prevention Built into the Software

Lantek Expert also integrates an Intelligent Collision Avoidance (ICA) algorithm, a crucial addition for high-speed fiber laser cutting operations. These machines often work with thin sheet metal and high-pressure gases, which can cause small parts or leftover material to shift, hop, or tilt unexpectedly—creating collision hazards for the cutting head.

The ICA system anticipates these risks in advance. It scans for elements—whether they’re cut components or residual material—that could potentially move and interfere with the cutting tool. The software then automatically applies micro-joints to stabilize those areas or removes them using predefined cutting rules.

It also recalculates the toolpath to prioritize safer sequences and ensures optimal timing of cuts. This is especially valuable for unattended operations, where maintaining a safe and uninterrupted cycle is critical.

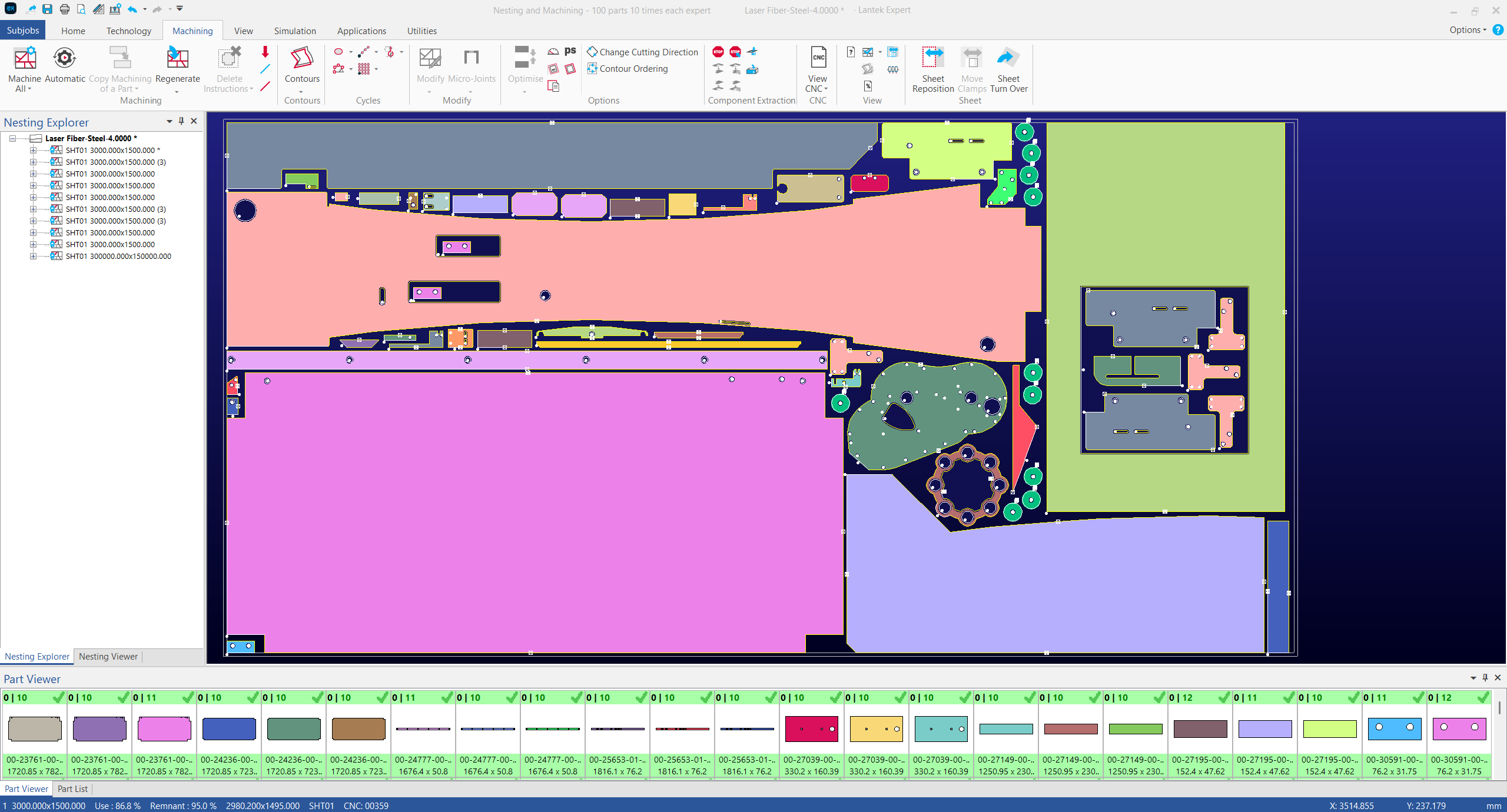

Advanced Nesting and Material Optimization for Greater Efficiency

Lantek Expert includes over 25 advanced strategies for cutting, punching, and shearing—each designed to improve overall efficiency and promote sustainability.

One of its most powerful advantages is its ability to optimize leftover sheet areas. After analyzing previously cut sheets, the software can identify usable zones and allow operators to nest new parts directly into these spaces using a simple drag-and-drop interface. This not only reduces waste but also maximizes the utility of each raw sheet.

Another highlight is Clean Cut technology, which applies to contours where neither lead-ins nor micro-joints should be used. The result: perfectly smooth, clean edges without compromise—particularly important in industries with high surface finish requirements.

Reliable Output, Smarter Workflow

Beyond improving the quality of finished components, Lantek Expert strengthens shop-floor safety, reduces material waste, and enhances programming control. Its combination of intuitive features and smart automation gives manufacturers the ability to streamline complex tasks, cut cycle times, and maintain a safe and reliable production environment.

For manufacturers looking to align quality, productivity, and sustainability in their sheet metal processes, Lantek Expert is a strategic asset built for modern fabrication.